Products

Contact us

Telephone: 13813577928

E-mail: atdry@126.com

Fax: 0519-88672859

Address: 8 Dongtang Road, Sanhekou Industrial Park, Zhenglu Town, Tianning District, Changzhou, China

Drum dryer series

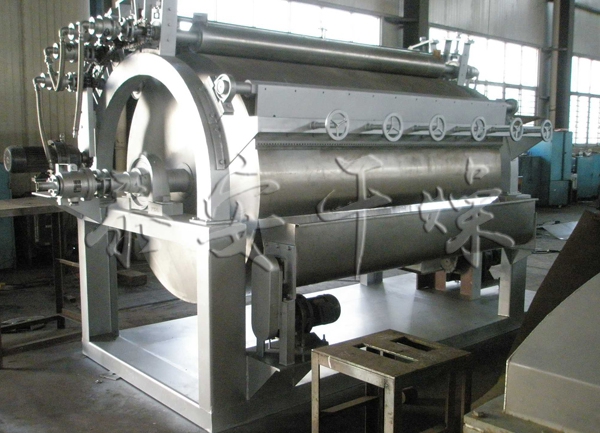

Hg series (single drum and double drum) drum scraper dryer

Detailed description

working principle

Drum dryer is a kind of internal heating conduction type rotary continuous drying equipment. The rotary drum adheres a thick material film through its lower material groove. The heat is transmitted to the inner wall of the drum through the pipe, and then to the outer wall of the drum, and then to the material film, so that the moisture in the material film can be evaporated, dehumidified, and the material containing moisture can be dried. The dried material is removed from the drum by the scraper installed on the surface of the drum, and then transferred to the screw conveyor under the scraper. The dry material is concentrated and packaged by the screw conveyor.

Performance characteristics

High thermal efficiency. Because the heat transfer mechanism of the drum dryer is heat conduction, the heat transfer direction is consistent throughout the operation cycle. Except for the cover heat dissipation and heat radiation loss, the rest of the heat is used for the evaporation of the cylinder film moisture, and the thermal efficiency can reach 70% - 80%.

Flexible operation and wide applicability. Many drying factors of drum dryer can be adjusted. For example, the concentration of feed, the thickness of coating film, the temperature of heating medium, the rotation speed of the drum can change the drying efficiency of the drum dryer, and many factors are not involved. This brings great convenience to the drum drying operation, so that it can adapt to the drying of a variety of materials and different production requirements.

Short drying time. The drying cycle of materials is generally only 10-300 seconds, which is suitable for heat sensitive materials. If the drum dryer is set in the vacuum, it can operate under the condition of decompression.

High drying rate. Because the coating film on the cylinder wall is very thin, generally in the range of 0.3-1.5mm, and the direction of heat and mass transfer is consistent, the evaporation intensity of 20-70kg · H2O / m2. H can be maintained on the surface of the coating film.

install

The machine is installed according to the general layout, the ground should be flat, the steam pipe inlet should be installed with pressure gauge and safety valve, and the steam inlet flange should be firmly connected.

Adaptive materials

It is suitable for drying liquid or viscous materials in chemical, dyestuff, pharmaceutical, food, metallurgy and other industries.

maintain

Check whether the rotating parts are jammed regularly. The chain wheel and other parts should be greased regularly, and the error of pressure gauge and other measuring devices should be corrected regularly. If the V-belt transmission parts are seriously worn, they should be replaced in time.

For the maintenance of motor and reducer, please refer to the operation and maintenance manual of motor and reducer.

debugging

After the installation of the machine, the test run should be carried out first

Touch the main motor to observe the correct rotation of the main drum.

Observe whether the main drum and transmission parts rotate flexibly, whether the steam inlet and outlet are connected, and whether the pressure gauge is within the working pressure range.

Start the motor, the main cylinder moves smoothly, and the temperature increases, after adding material, adjust the motor speed and material uniformity on the drum to control the final water content of the material.

Start the winch motor, output the dry finished material, and adjust the speed of the winch motor according to the dry finished product.

technical specifications

| Specifications | Drum size | Effective heating area(m2) | Drying capacity kg.H2O/m2.h | Steam consumption kg/h | Electric machine power(Kw) | Dimensionsmm | Weight kg |

| HG-600 | Φ600×800 | 1.12 | 40-70 | 100-175 | 2.2 | 1700×800×1500 | 850 |

| HG-700 | Φ700×1000 | 1.65 | 60-90 | 150-225 | 3 | 2100×1000×1800 | 1210 |

| HG-800 | Φ800×1200 | 2.26 | 90-130 | 225-325 | 4 | 2500×1100×1980 | 1700 |

| HG-1000 | Φ1000×1400 | 3.30 | 130-190 | 325-475 | 5.5 | 2700×1300×2250 | 2100 |

| HG-1200 | Φ1200×1500 | 4.24 | 160-250 | 400-625 | 7.5 | 2800×1500×2450 | 2650 |

| HG-1400 | Φ1400×1600 | 5.28 | 210-310 | 525-775 | 11 | 3150×1700×2800 | 3220 |

| HG-1600 | Φ1600×1800 | 6.79 | 270-400 | 675-1000 | 11 | 3350×1900×3150 | 4350 |

| HG-1800 | Φ1800×2000 | 8.48 | 330-500 | 825-1250 | 15 | 3600×2050×3500 | 5100 |

| HG-1800A | Φ1800×2500 | 10.60 | 420-630 | 1050-1575 | 18.5 | 4100×2050×3500 | 6150 |

Note:If the customer needs, we can design and manufacture the upper feeding double drum dryer for customers.

Pre:No Prev