Products

Contact us

Telephone: 13813577928

E-mail: atdry@126.com

Fax: 0519-88672859

Address: 8 Dongtang Road, Sanhekou Industrial Park, Zhenglu Town, Tianning District, Changzhou, China

Spray dryer series

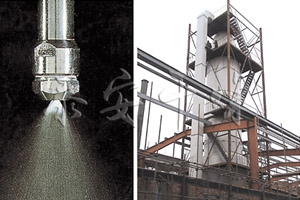

YPG series pressure type spray (cooling) dryer

Detailed description

The pressure type spray drying granulator is a device which uses pressure atomizer to atomized liquid or slurry material into tiny droplets by means of pressure of diaphragm pump, so that the surface area is significantly increased. It can be quickly dried (ten seconds to tens of seconds) by hot exchange with hot air to obtain powder or fine particle products.

characteristic:

Fast drying speed, suitable for heat sensitive materials;

The product is spherical particles with uniform particle size, good fluidity and solubility, high purity and good quality;

Wide range of applications, such as hot air drying, granulation, cooling granulation, spray crystallization, spray reaction, etc.

It can be equipped with fine powder return and rewetting agglomerating system to meet the requirements of users for material particle size.

The operation is simple and stable, the control is convenient, and the automatic operation is easy to realize. The product particle size, bulk density and water powder can be adjusted within a certain range

Application:

Food, medicine, chemical industry, dyeing, ceramics, biochemistry, pesticide, plastics, etc. are suitable for liquid with corresponding fluidity.

Technical parameters:

| Model | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Water evaporation kg/h | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Dimensions(Φ×H)mm | 1600×8900 | 2000×11500 | 2400×13500 | 2800×14800 | 3200×15400 | 3800×18800 | 4600×22500 |

| High pressure pump pressure Mpa | 2-10 | ||||||

| Power(Kw) | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| Inlet air temperature℃ | 300-350 | ||||||

| Water content of product% | ﹤5(Up to 0.5) | ||||||

| Material recovery% | ﹥97 | ||||||

| Electric heating kw | 75 | 120 | 150 | When the temperature is lower than 200 ℃, the specific calculation shall be based on the actual situation | |||

| Electric plus steammpa + kw | 0.5+54 | 0.6+90 | 0.6+108 | ||||

| Hot blast stove kcal / h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

Note: some parameters are adjusted according to different materials, and the design shall prevail.