Products

Contact us

Contacts: Zhang Ya (General Manager)

Telephone: 13813577928

E-mail: atdry@126.com

Fax: 0519-88672859

Address: 8 Dongtang Road, Sanhekou Industrial Park, Zhenglu Town, Tianning District, Changzhou, China

Telephone: 13813577928

E-mail: atdry@126.com

Fax: 0519-88672859

Address: 8 Dongtang Road, Sanhekou Industrial Park, Zhenglu Town, Tianning District, Changzhou, China

- High speed mixer

- The machine can mix fine powder, coagulated powder or more than two kinds of powder with certain moisture. For example, it can also achieve the mixing effect for the additives with small amount of phase.MORE+

- DSH series conical twin screw screw mixer

- There are four main forms of motion: 1. The spiral rotates along the wall, making the material move in a circle along the cone wall; 2. The rotation of the screw causes the material to rise along the spiral from the bottom of the cone; 3. The common motion of the spiral is the rotation of the screw Part of the material in the spiral cylinder surface is absorbed into the spiral cylinder by the combined rotation movement, and a part of the material in the spiral cylinder surface is discharged radially to the cone under the action of the centrifugal force of the spiral rotation; 4. The rising material is reduced by its own gravity. The four kinds of motion produce convection, shear and diffusion in the mixer, so as to achieve the purpose of rapid and uniform mixing.MORE+

- 30b series universal pulverizer

- The pulverizing unit is composed of pulverizer, ESC material collecting box and ESC vacuum cleaner. To solve the problem of dust flying in the crushing process. The working principle of this machine is that the materials enter the crushing chamber and are crushed under the impact, shear, friction and mutual impact of the teeth between the high-speed rotating movable gear plate and the fixed gear plate, and the required powder is obtained after screening through the screen. The pulverizer, material collecting box and vacuum cleaner of this pulverizing unit are all made of stainless steel. It meets the requirements of GMP.MORE+

- 30b-c series pulverizer

- The pulverizer consists of pulverizer, ESC material collection box and ESC vacuum cleaner. Solve the problem of dust flying in the process of crushing. The working principle of the machine is that the material enters the crushing chamber and is crushed under the impact, shear, friction of the teeth and the mutual impact of the materials between the high-speed rotating movable gear disc and the fixed gear disc. After screening, it becomes the required powder. The pulverizer, material collection box and vacuum cleaner of the pulverizer are all made of stainless steel. It meets the requirements of GMP in drug production.MORE+

- CSJ series rougher

- This machine is suitable for pharmaceutical, chemical, metallurgical, food, construction and other industries. Processing hard and hard materials, including plastics, copper wire, Chinese herbal rubber, etc., can also be used as the supporting equipment for the previous process of micro pulverizer and ultra-fine pulverizerMORE+

- WFJ series superfine pulverizer

- This series of micro pulverizer is composed of main engine, auxiliary machine and electric control unit. It is compact in design and reasonable in structure. It has air separation type, no screen and no net. The machine is equipped with a grading mechanism, which can complete crushing and grading at one time. The negative pressure transportation makes the heat generated in the chamber continuously discharged during the grinding operation, so it is also suitable for the crushing of heat sensitive materials. This machine is suitable for a wide range of applications, the production process is continuous, and the discharge particle size is adjustable; it can process the crushing and grading of chemicals, food, medicine, cosmetics, dyes, resins, shells and other materials.MORE+

- Rly series oil and gas hot air stove

- The fuel burns through the burner to produce high temperature gas. With the help of the hot blast stove with enhanced heat exchange measures, the heat of high-temperature gas is transferred to the heated air, and the temperature of high-temperature gas is reduced to 250 ℃ after heat dissipation and then discharged into the atmosphere. The air to be heated is forced into the hot blast stove through the fan of the selected drum. After heat absorption, the temperature rises to the rated value and is sent out from the hot air outlet. When the hot air temperature reaches the upper limit of the rated temperature, the burner will automatically stop burning or automatically switch to small flame combustion. When the hot air temperature drops to the rated lower limit temperature, the burner will re ignite or turn to high fire combustion, and the heating speed is OK Adjust the opening of the air inlet valve to achieve.MORE+

- JRF series coal fired hot blast stove

- The furnace is a universal hot air device, which can be used with drying equipment of various materials. It is widely used for heating and dehumidification of grain, seed, feed, fruit, dehydrated vegetable, Lentinus edodes, Auricularia, tremella, tea, tobacco leaf and other agricultural products, food, medicine, chemical raw materials, light and heavy industrial products. It can also be used for heating of various facilities and dehumidification of warehouse.MORE+

- ZS series circular vibrating screen

- ZS series layered screen is suitable for flow operation, and it is an ideal equipment for continuous screening and discharging with different proportion of large and small particles. The machine is composed of hopper, oscillation chamber, coupling and electric machine. The oscillation chamber is composed of eccentric wheel, rubber cushion, main shaft, bearing, etc. The adjustable eccentric weight is transmitted to the center line of the main shaft through the motor drive. Under the unbalanced state, the centrifugal force is generated, which changes the material strength and forms the track vortex in the screen. The amplitude of the screen can be adjusted according to the size of the material. The whole machine has compact structure, small volume, no dust, low noise, high quality, low energy consumption, convenient movement and maintenance.MORE+

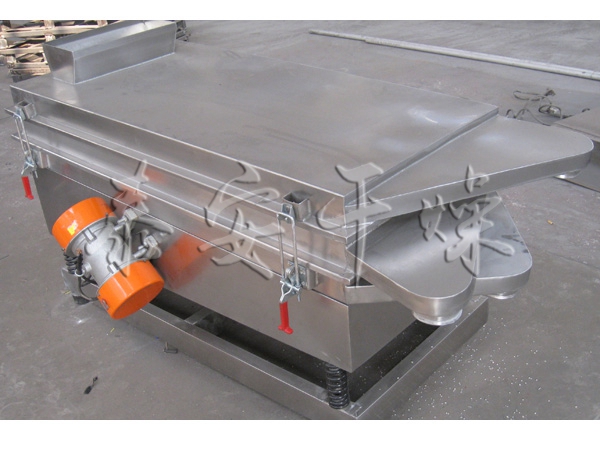

- FS series square vibrating screen

- The upper part of the machine adopts quick dismantling handle to connect the whole machine into a whole, and the upper cover is fully sealed to effectively prevent dust flying due to vibration during screening. The vibrating electric machine is installed in the lower part of the screen body, which effectively ensures the compact structure of the material. The spring vibration damping is used in the lower part of the screen body to make the whole machine work in a stable state. The bottom base adopts adjustable type, which can adjust the tilt angle of the screen surface when passing the sieve, so as to achieve good screening effect according to the material characteristics.MORE+

- ZSL - Ⅲ series vacuum feeder

- ZSL - Ⅲ series vacuum feeding machine is the third generation of new vacuum feeding machine newly developed by our company. It has the advantages of fast feeding speed, long service cycle, convenient operation, clean and sanitary, and meets the requirements of GMP.MORE+

- QVC series pneumatic vacuum feeder

- Pneumatic vacuum feeder uses compressed air to produce high vacuum through vacuum generator to transport materials. It does not need mechanical vacuum pump. It has the advantages of simple structure, small volume, maintenance free, low noise, convenient control, elimination of static electric current of materials and meeting GMP requirements. The high vacuum produced by the vacuum generator eliminates the stratification of the transported materials and ensures the homogeneity of the mixed materials. It is the preferred equipment for automatic mechanical feeding of tablet press, capsule filling machine, dry granulator, packaging machine, pulverizer and vibrating screen.MORE+